GBS has partnered with strategic manufacturers to meet the strenuous demands of semiconductor processes, which often involve corrosive chemicals, plasma, and high temperatures. Our expertise extends to specialized areas like semiconductor coating, ensuring comprehensive solutions for the industry’s challenges.

All our solutions, including our specialized semiconductor coating services, are designed to improve the quality and performance of the manufacturing process. Apart from high durability, we offer customised solutions to cater to the diverse needs of our customers.

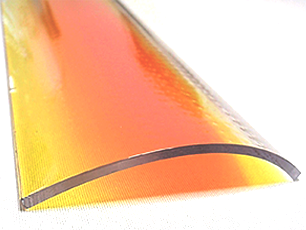

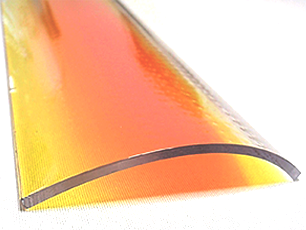

Lens, Filters & Mirror

GBS partners with various optics manufacturers with over 30 years of experience in the design and manufacturing of optical parts.

We supply a wide range of optical parts such as Filters and Lenses for all major Wafer Steppers and Scanners. In addition, we offer Repair on Beamsplitter, Optical Isolator and Retarder plates for most Metrology tools.

Benefits

- High temperature resistance

- Customisable optical parts

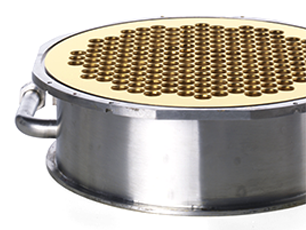

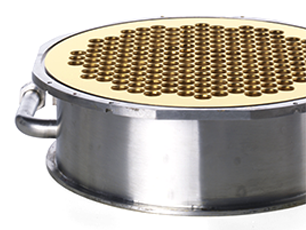

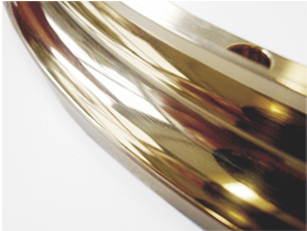

Coating for RTP, EPI & CVD

Within the RTP process, which involves heating silicon wafers to high temperatures (over 1,000 °C) on a timescale of several seconds or less with high-intensity Halogen lamps, semiconductor coating plays a vital role.

During the process, Chemical Vapour Deposition severely strains the mechanical and optical components within the plasma chamber due to the exposure to high temperatures, chemical gases and aggressive plasma. Hence causing degradation in the asset’s performance.

We have in-depth brand Cialis knowledge of materials and the application of materials. Together with our partners, we provide top-quality refurbishment services for these critical components to many customers in Asia.

Benefits

- High temperature resistance

- High plasma resistance

- High corrosive chemicals resistance

- Longer life expectancy

- Lower production downtime & replacement cost

Common Problems Faced

- Low product life span resulting in frequent change of parts

- Less than optimal throughput yield

- Frequent asset breakdown / unscheduled downtime

- Exposure to corrosive chemicals and extreme conditions

GBS Singapore Pte Ltd is proudly powered by WordPress